Delta > Data Center Infrastructure > Delta InfraSuite Manager – Data Center Infrastructure Management (DCIM)

The Operation base model of InfraSuite Manager (EMS3000) is the basic platform that shows real-time device alerts and the datacenter floor plan with graphs. It can also provide real-time suggestions to assist datacenter managers for proper reactions.

The Operation base model provides the fundamental DCIM platform. Extensional function modules can be added according to the demand of the enterprise or organization. This system also supports integration with third-party devices.

Monitor All Equipment

The BIM 3D functional module of InfraSuite Manager applies BIM technology to provide a 3D visualized platform. Compared to a traditional 2D layout, BIM 3D provides datacenter managers with realistic and interactive scenes and a more intuitive UI interface that greatly improves the user experience.

Delta’s BIM 3D functional module applies the standardized and parametric 3D modeling technology widely used in the market. Through its own computing system, it transforms the complicated information of the traditional 2D graphic design into a more intuitive and intelligent 3D interface.

Advantages

Operation Interface

Monitoring and Management

Sufficient power supply is the foundation of consistent uptime for numerous servers, network devices and infrastructure facilities in data centers. However, this comes with the tremendous power consumption that has always been a critical challenge for data center managers. Therefore, how to reduce power consumption while maintaining the best availability of data center operation is a critical mission of the management team. The Energy Management Module is designed and developed for resolving this issue.

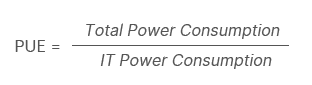

PUE (Power Usage Effectiveness) is the indicator for measuring power consumption. It is reported from DIGITIMES that, if the PUE can be lowered by 0.1 in a 100KW data center, there will be approximately US$10,000 electricity costs saved annually. It is undoubtedly important for data center managers to make their best efforts to manage energy consumption effectively.

The Energy Module contains the functions of energy measurement, PUE calculation, electricity tariff formula, and historical data analysis. In addition, it includes organizational energy classification and management mechanisms. With time and experience operating this system, datacenter managers develop greater agility for managing energy consumption. This module can transform energy consumption data collected from power meters, UPS (Uninterruptible Power Supply), PDU (Power Distribution Unit) and environment detectors into dynamic charts and graphs, including line charts, bar charts, and pie charts based on user preference.

Electricity Fee Calculation

Energy Usage Analysis

When an event occurs, the Incident Module can help data center managers restore equipment to normal operation with the best repair quality in the shortest possible time, reduce business losses of the enterprise or organization, and ensure the best operation and maintenance efficiency and service continuity.

Asset Management is the core function of DCIM management activities. In a datacenter, there can be thousands of assets including infrastructure facilities such as power and cooling. There are also IT assets such as servers, storage, networks, and others. Constantly tracking and monitoring these assets are important tasks for datacenter managers. In the case of assets without proper management, it often leads to a higher mean time to repair (MTTR) and lowering the availability of the data center’s equipment.

The Asset Management function module provides an interface that is easy to use and monitor, allowing the datacenter managers to classify and inquire about detailed information on power, cooling, network, and servers. It can also generate a power path diagram and network topology according to the device’s downstream relationships. The simple, real-time and easy-to-use operation platform enables users to quickly and clearly identify the status of the power and IT assets.

Advantages

Rack Management

Well-designed rack front and rear views make it easier for datacenter managers to quickly and clearly get device locations and capacity status at a glance.

Device Relationship Analysis

3D Visualization

This function can automatically generate a 3D view according to the floor plan design, and can perform operations such as cruising, rotating, zoom in and out.

The Capacity Module allows data center managers to plan for the future more effectively through the use of detailed data on rack space, weight, network, power and cooling capacity in the data center. For example, Capacity Module helps data center managers evaluate resource consumption, making it easier for them to plan and decide on the future allocation and most suitable installation locations for IT devices.

Advantages

Rack Management

The Work Order Module provides a highly customizable platform that enables users to design work order templates for different management purposes. Different variables such as names, types, priority, schedule, roles of tasks can then be set by the administrator. This helps users not only simplify and integrate the process of change management, but also extends the life cycle of data center operation.

Advantages

The Asset Inspection Module can be used with a user-friendly mobile app which makes it smarter and more efficient for an inspector to complete his/her inspection process. Customizable templates can be designed for different types of assets. Users can also upload photos of the inspected assets to InfraSuite Manager. Unique QR codes of each asset can be generated by the system, making tasks more intuitive.

The Analytics Module is not just for a single site but for the entire organization. The electricity tariff formula can be customized for each department. In terms of detailed energy analysis, Delta offers diverse scenario analyses, including energy usage KPI, comparison, energy combination analysis, abnormal energy usage ranking, and energy usage estimation. In terms of asset analysis, it can provide rack power ranking by average and peak power for organization, asset expiration report and asset inspection analysis.

Machine Learning Function

Because each project is different in configuration and application, the existing EMS3000 historical database (1 year) must be used for the learning materials to model and predict.

The Smart Energy functional module of InfraSuite Manager is designed for optimizing the power consumption efficiency of the data center. System diagnosis is carried out based on the information collected from devices to optimize the cooling system’s operation. This helps the data center to achieve the goal of overall energy saving and carbon reduction, and helps enterprises move toward environmental sustainability.

Advantages

Features